Our technology

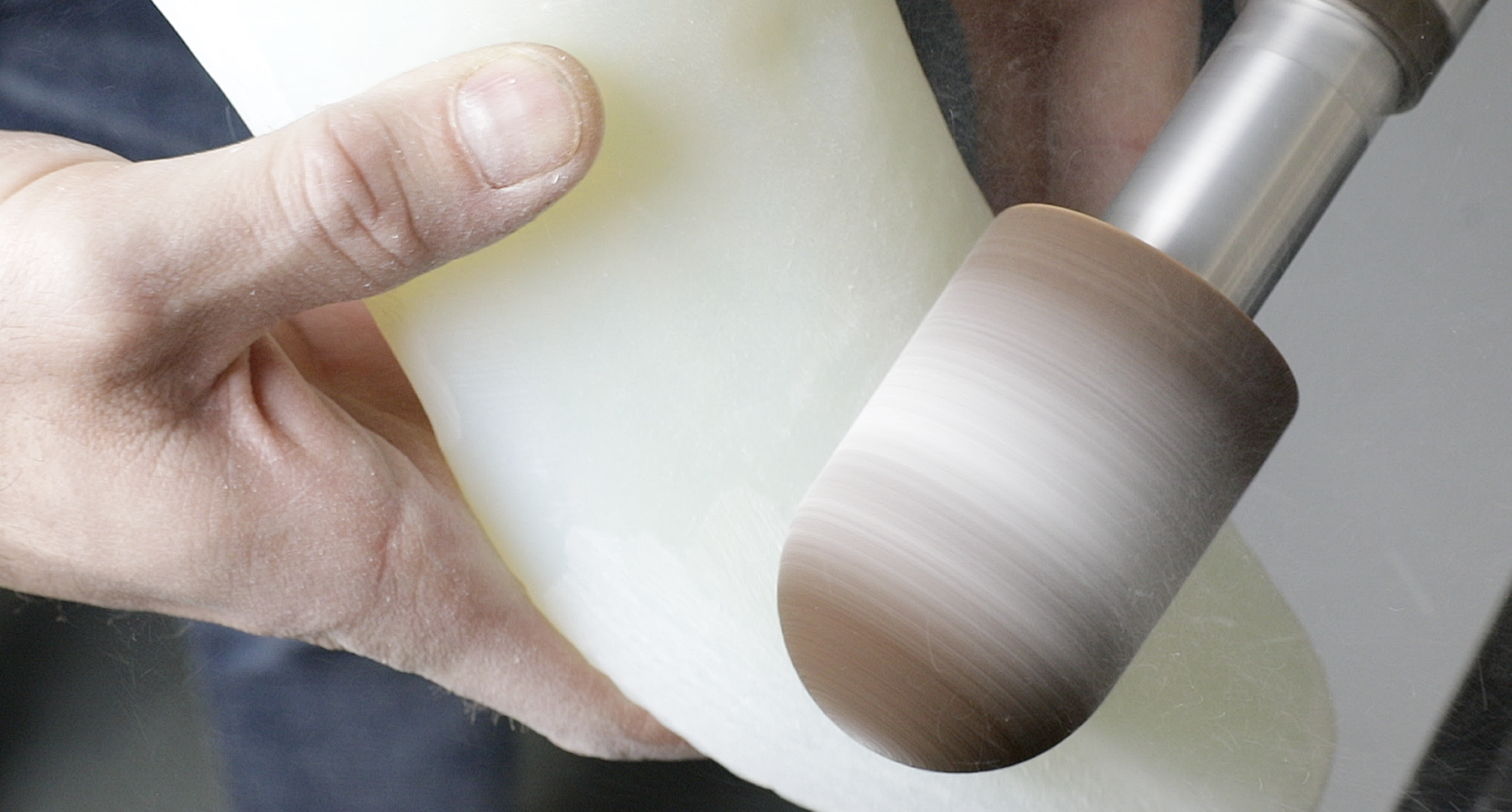

The 3D-printed last from Dreve offers outstanding properties for the production of custom shoes. It is available for you on short notice without long delivery times and is manufactured by us in an energy- and resource-saving way. At the same time, it is in no way inferior to traditionally crafted lasts. Thanks to the digital workflow, you always receive a highly accurate product that can be reproduced at any time.

Properties

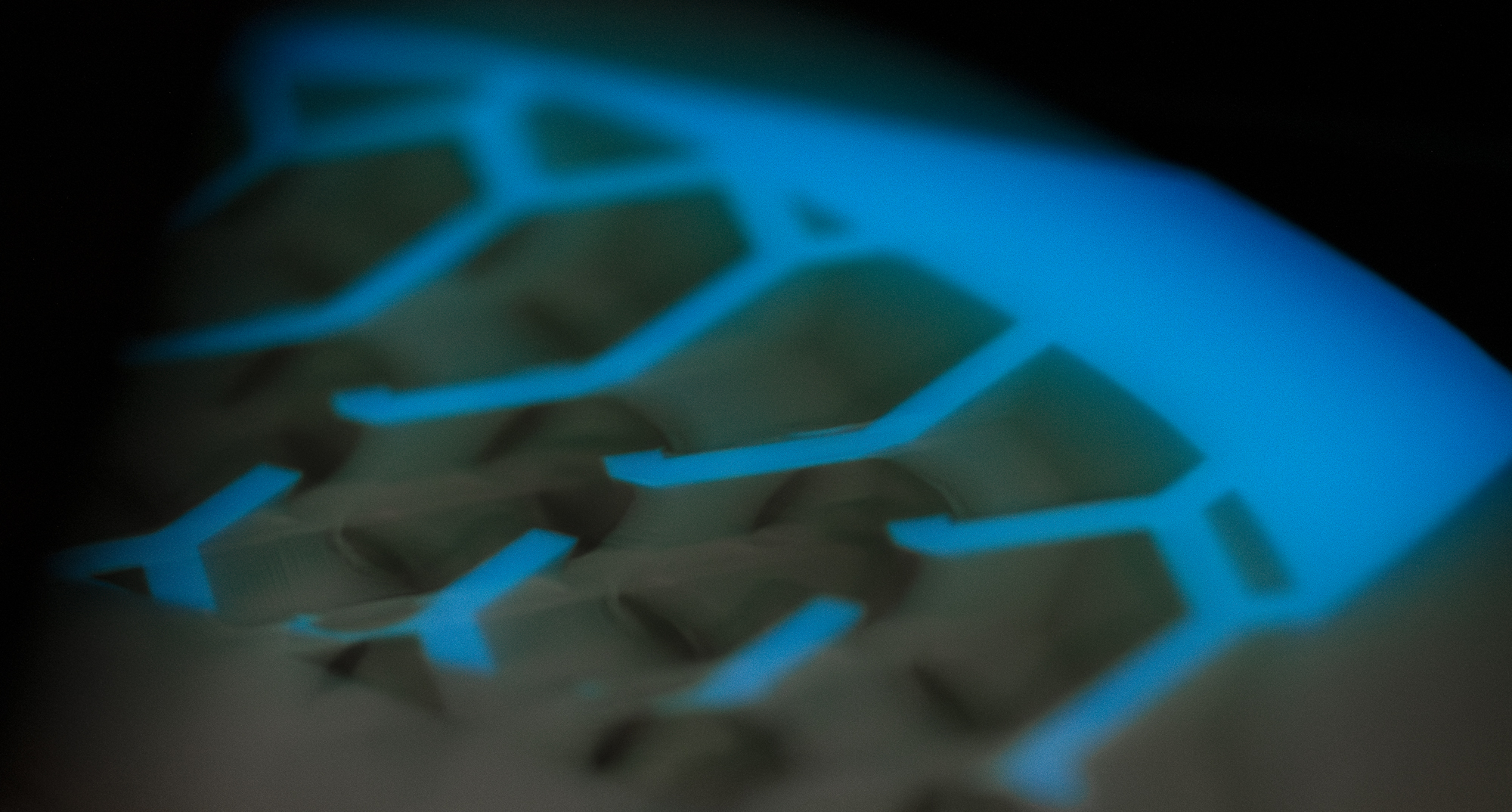

Why DLP Printing?

Waste and sustainability are increasingly significant and crucial issues in today´s world. Wood moldings fit ideally into this profile of requirements, but are manufactured through subtractive methods, leading to a considerable amount of unused wood waste. Additive manufacturing meshes precisely with this approach. In the manufacturing process generally referred to as 3D printing, the component is built up layer by layer, i.e. material is gradually layered on top of one another, and only in the area that will later constitute the component. The material used is therefore incorporated into the final component almost completely and without waste.

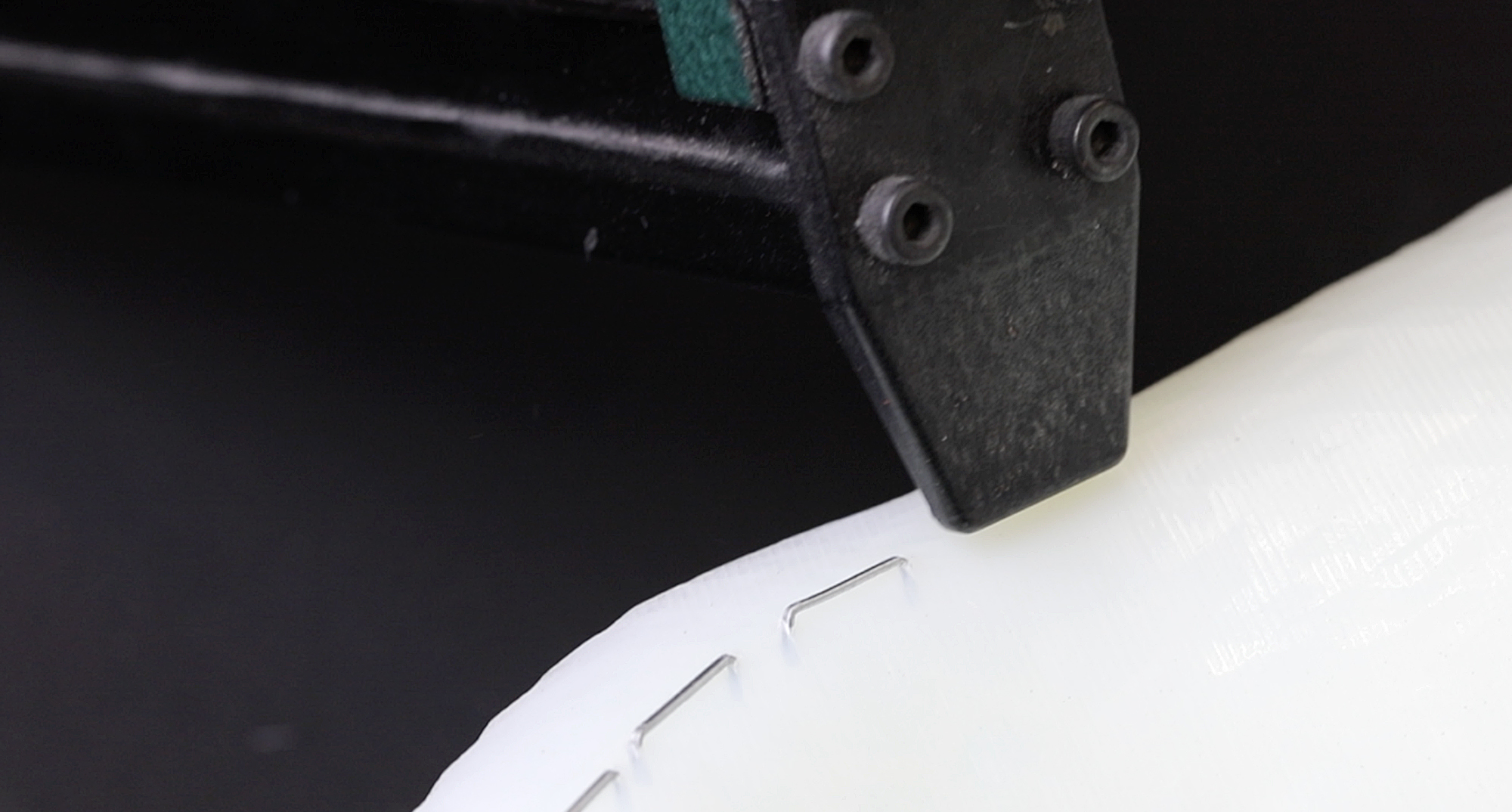

In the FDM printing process, the material used is heated and recorded layer by layer with a nozzle in the form of a melted plastic strand. Two things in particular are disadvantageous here: Firstly, the nozzle has to approach each individual point within a layer once, which means high production times for large components. Secondly, the material cools after deposition, which means that the next layer, again hot and molten when extruded from the nozzle, is deposited on a cold layer. Stresses and a less than ideal layer bond, leading to mechanical weak points, are the result.

In 3D printing with light-curing plastics, material is cured by means of UV light and thus chemically shaped by molecular bonds. The bond between the layers is also based on cross-linking of the molecules, which makes the layer bond very stable and gives the finished component almost isotropic properties - the component can be loaded equally in all directions.

The benefits of these advantages are consolidated in 3D-printed lasts by Dreve.

Sustainability

Nowadays, there is an increasing awareness of sustainability and ecological products. This idea affects both, the private and commercial sectors - and therefore also the work of orthopedic shoe technicians in their workshops. Shoe lasts are no exception, even if the aim should always be to use the last for as long as possible and for as many pairs of shoes as possible for reasons of efficiency alone, provided the patient's foot does not change significantly.

However, if this is the case, the disposal of the last must be resolved. In this context, our 3D-printed last is on par with the wooden last in every aspect. The resin used is free from toxins, allowing for the disposal of the molding with regular household waste. Thermal recycling for generating heat or electricity is seamlessly feasible. Alternatively, you have the option to return the skirting board to us for recycling through Dreve.

Disposal options of the 3D-printed last from Dreve:

✓ Disposal via household waste

✓ Thermal recycling possible without any problems

✓ Return to Dreve for free disposal

Our experts

Opting for 3D printing is an innovative step in your overall workflow. However, the initial stages, particularly the commencement and implementation, can pose challenges, not only for beginners. Our additive manufacturing and 3D printing experts are happy to support you on your way. We'll be pleased to guide you expertly through the process. For more than seventy years, Dreve has stood for high-quality and reliable products in medical applications.

As a provider of medical products, our top priority is ensuring the absolute satisfaction of our customers. Our experts therefore offer real added value for you – whether you are an experienced user of digital technologies or an ambitious newcomer. Feel free to contact us at any time!